Why we choose to build our vanities in the USA / April 2025

The Furniture Collection: Our Commitment to 100% American-Made Vanities

It’s the difference you can see and feel.

“Why don’t you just outsource your manufacturing?”

We’ve heard this phrase a few times. Usually someone suggests it when we are talking about the challenges of manufacturing, when one of our best craftsmen calls in sick, or one of our machines decides it wants to have a case of the Mondays. And honestly, like a lot of things in life, sometimes the grass does seem greener on the other side of the fence.

But when we walk through our factory, and one of the vanity builders comment’s how much he enjoys building the Furniture Collection because he loves the quality, we know why we choose to stick with manufacturing here in the USA. American craftsmen, American materials, and American pride.

Behind the Scenes: Timberline’s In-House Manufacturing Process

We wanted to share a bit of the behind the scenes of the process of building a vanity here in the USA. It helps explain why we choose to keep the process in house.

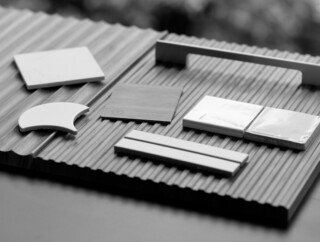

Our founder’s dad sometimes still talks about the day he used to do engineering drawings by hand with a ruler and pencil, using tracing paper to get neat copies. These days, we have it a lot easier; our design team uses a cabinet construction software that allows them to efficiently draw all the parts that go into a vanity, and make sure that all the hardware will work.

Every cabinet that comes through our shop gets personal attention from our drafting and design team. We really love this part of the process, because it makes it easy for any cabinet to be customized – changing the size, the number of drawers, or a ton of other details means that we can make exactly what you need for your bathroom.

The drawing team then sends the vanity to our shop floor where the machine operators take over and cut the vanity parts on a CNC. Back when Timberline first started, this process was way more manual and relied on the saw guy, Ernesto, figuring out how to get the most parts out of a sheet and cutting them all manually.

Cutting these parts on a CNC means Ernesto can now get way more out of a sheet, and cut more intricate designs. Reducing waste and our economical footprint is a key point of why we choose to manufacture in the USA.

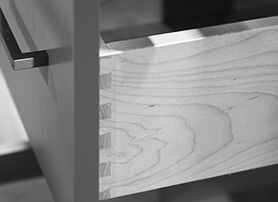

After we cut all the parts for a vanity, it heads to finishing—one of the most important parts of what we do. Every piece is hand-sanded before it even sees a layer of finish. The combination of great materials and this hands-on process is what really has the most impact on the quality of any vanity, not just ours.

The folks in our finish room have been doing this for years, and it shows. The process goes: sanding, primer, more sanding, top coat, sanding again, and then a final top coat. It’s a slow process that takes real skill. If we did outsource or import, not being able to guarantee high quality materials and finishing would really take away from our products.

Once everything is cured, we start the assembly process. When you walk through the factory, assembly looks like it should take a long time, but it’s actually one of the fastest parts of the process. The builders can whiz a vanity through assembly, clamp and glue it, add the drawers and doors, and install hardware in barely any time at all.

We’ve noticed other manufacturers using careful wording to say their vanities are “Assembled in the USA”. We feel this is a bit of a cheat as it’s most likely they are just doing this to fit more in a container; vanities are quite bulky, so flat packing means you can cut shipping costs.

We feel that fully making our vanities in the USA means that we can get the best quality, offer the most customization, and produce our cabinets in a sustainable and Eco-friendly way.

Why We Don’t Outsource Our Manufacturing

We are extremely lucky to have a great team of craftsmen. One of the best parts of local manufacturing is that you get to support the local community and their family. Rosa’s daughter just graduated, Armando just got married, and Jackson just moved to a new apartment. Working everyday with our team means we get to know them, and experience life with them. It’s one of the main reasons we choose to not move our manufacturing overseas.

Yes, the labor might be cheaper, but at what cost? We can’t vouch for the working conditions or wages of the employees who would make our vanities, and we care about that. We want to make a product that is ethical and that supports our local communities.

Another reason why overseas manufacturing can be cheaper, is because other countries have less regulations regarding the environment. We choose to manufacture in the USA to ensure that we are conscious of our carbon footprint.

We know our customers care about how their vanities are made, and we don’t feel that moving production offshore to a country that has fewer regulatory measures for the safety of the environment and its workers is not worth the dollar savings.

At Timberline, we’ve chosen the harder road—and we’d choose it again every time. Building our Furniture Collection vanities entirely in the USA isn’t just a manufacturing decision, it’s a reflection of who we are. It means we get to stand behind every cabinet that leaves our factory with complete confidence in the materials, the craftsmanship, and the people who made it.

We know this approach isn’t the norm in our industry. But for us, it’s never been about doing what’s easiest—it’s about doing what’s right. Right for our customers, right for our team, right for our communities, and right for the planet.

If you get a Timberline vanity, take a moment to admire it, and feel some pride! Know that you’ve helped too, that you’ve supported Rosa and her incredible family, that you helped Ernesto, Jackson, Armando, and the entire family at Timberline, and our surrounding community.

Thank you for being a part of what we stand for!

Cart

Cart